Micro Injection Molding

We specialize in manufacturing micro plastic components with a size range of 1 to 20 mm and a weight range of 0.0001 to 6 g. We offer a wide selection of materials, including high-temperature materials such as PEEK, PEI, PESU, high-value materials such as PLLA, PLGA, as well as silicone (PDMS), suitable for applications in the medical, electronic, connector, gear, optical, and wearable device fields. Our services cover the entire process from development design, prototyping, tooling, trial production, to mass production. We are ISO 13485 certified and have a cleanroom facility that complies with the Fed 209E Class 10,000 standard.

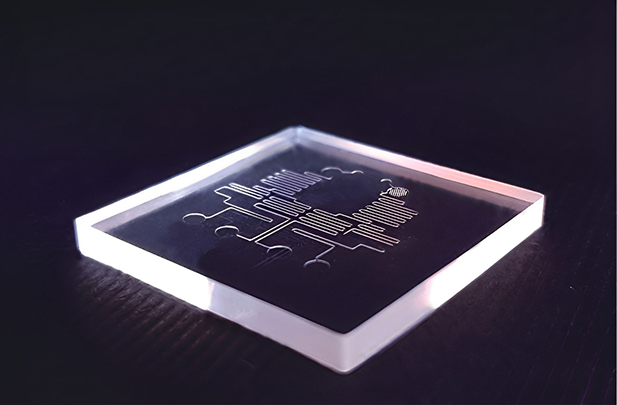

Microfluidic Biochip

By combining advanced semiconductor processes and traditional mold technology with precision machining and LIGA processes, and aided by micro-injection molding technology, we are able to meet customers' demands for mass production of various types of detection, encapsulation, and organ chips.

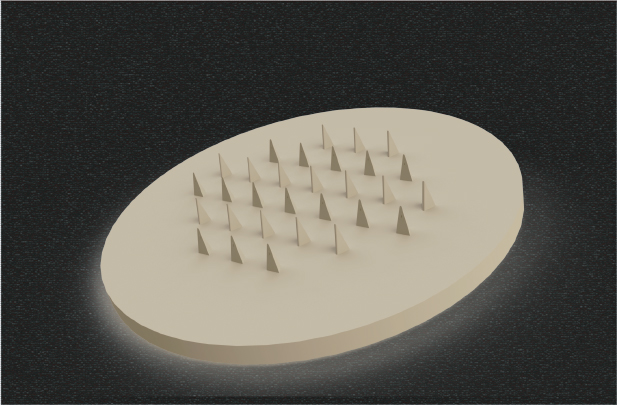

Microneedle

Partnering with pharma to develop solid, hollow and absorbable microneedle patch. Providing turnkey production line and validation services for large molecule absorption.

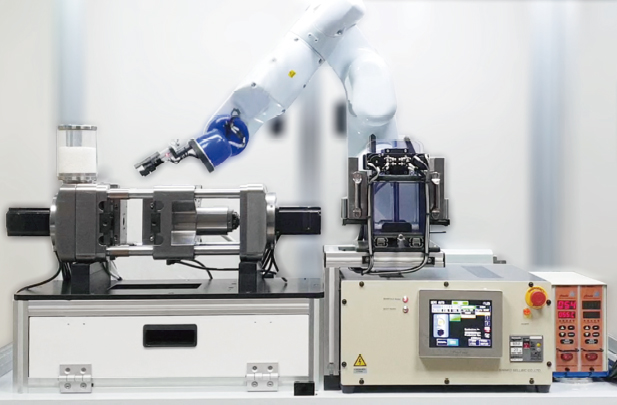

Read MoreMicro Injection Molding Machine

Micro Injection Molding Machine - The micro injection molding machine that is world-renowned for its small size, for consuming the least resin, and for its ability to produce small components.

Micro Injection Molding - We assist our customers in developing micro injection molding technology and help integrate this technology into their mass production process for the following products:medical components, precision electronic parts, connectors, small gears, optical elements, wearable devices, and so on.

Hot Runner Systems

Hot Runner Systems - We market our successful brand AMOLD world-wide and provide the support to enable our customers to produce tailor-made plastic products by hot runner systems.

Based on years of industry experience, we launched the "Hot Runner Workshop" program which provides complete solutions to our customers' molding issues for hot runner systems.

Liquid Silicone Rubber (LSR) Cold Runner Systems

Liquid Silicone Rubber (LSR) cold runner systems -The demand for Liquid Silicone Rubber (LSR) products is growing. We put a lot effort to innovate the LSR cold runner system for helping meet growing need in the market.

We provide LSR-mold, LSR-cold deck, coaxial shut-off module, uniform heating system and total solution to help you molding silicone (R), dual silicone (R+R), insert plastic (P+R), insert metal (M+R). Therefore, help our customers to get more efficient for LSR injection molding. Improve the quality, reduce waste of material and speed up production.

Read More