Aggregating Experience, Leading the New Trend in Medical Micro-Molding

2024-06-17

Anntong, with its thirty years of experience in plastic molding, has become a new force in the field of medical micro-molding, bringing fresh momentum to the industry's development. As a significant player in the plastic molding industry, Anntong has collaborated with renowned companies such as ASUS, Quanta, and Wistron, accumulating rich cooperative experience. Ten years ago, the company began to transition, focusing on representing Japanese micro injection molding machines, providing plastic micro-molding solutions for the electronics industry. In recent years, with the increasing demand for outsourcing from medical clients, the medical industry has become an important part of the company’s business.

The best partner for micro injection molding

Anntong has numerous advantages in medical micro-molding outsourcing. Firstly, we provide comprehensive services, including product design, mold design, and injection molding, ensuring seamless integration from design to production. As a CDMO (Contract Development and Manufacturing Organization), Anntong offers full support from product design and mass production to product certification. Secondly, the company possesses high-precision manufacturing technology and equipment and is ISO 13485 certified, ensuring products meet medical standards. The production area is equipped with cleanrooms, meeting high cleanliness requirements to ensure the production of high-quality, contamination-free products. Additionally, Anntong primarily focuses on plastic injection molding, integrating other industrial chains, including metal micro-molding processing and PCB assembly outsourcing, providing diversified manufacturing solutions, and becoming an industry-leading partner in medical micro-molding.

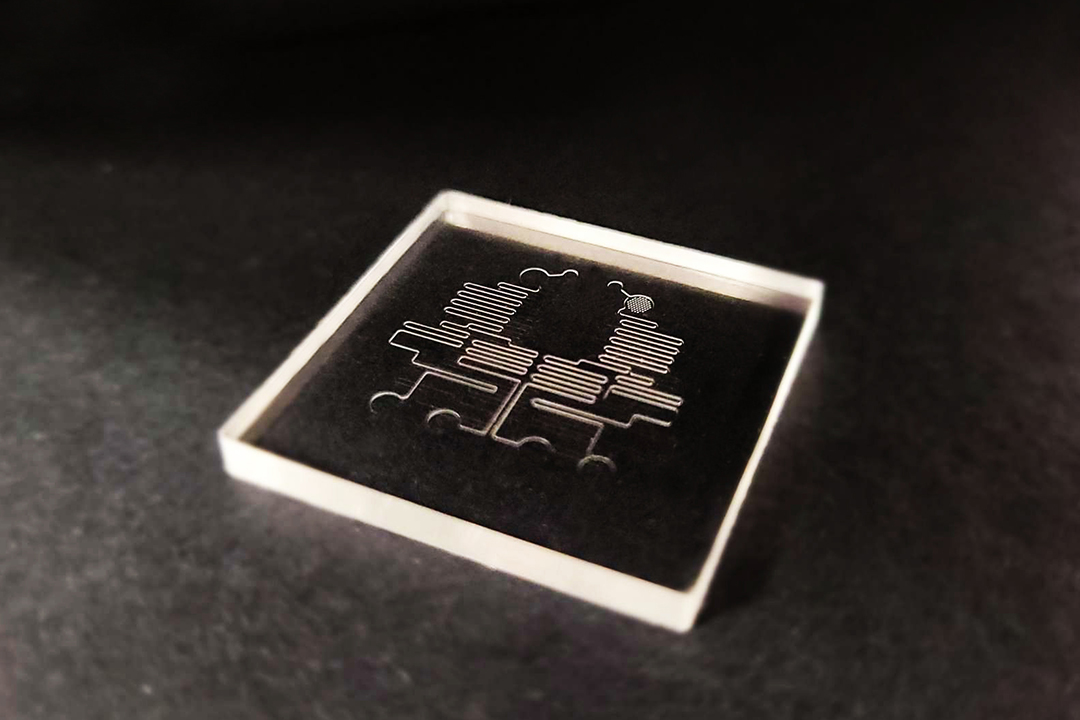

Microfluidic technology innovation

Recently, Anntong has ventured into the development of microchannel biochips, demonstrating significant potential in medical applications. This technology can simulate a 3D environment close to the human body's internal conditions, effectively replacing or supplementing traditional 2D cell culture and animal experimental models. Through this chip, we can more accurately analyze biological mechanisms, improve the accuracy of drug testing, and accelerate drug development. At the same time, it can significantly reduce the demand for animal experiments, thereby reducing the ethical risks of clinical drug trials, making it an important technological innovation in the future of pharmaceutical research and development.

Anntong has extensive experience in production and research and development, making it one of the few facilities compliant with regulations. We can bridge the gap between customer laboratory research and clinical trials to large-scale production, providing contract manufacturing services that are flexible, fast, and customized. Additionally, we not only offer contract manufacturing services but also assist customers in considering manufacturability in the early stages of product design to ensure the success rate of products and reduce resource waste.

With its rich technical and service experience, Anntong has brought new development opportunities to the field of medical micro-molding. We look forward to continuing to innovate and upgrade our technology in the future, providing customers with more diversified and high-quality products, and jointly promoting the progress and development of the medical industry.