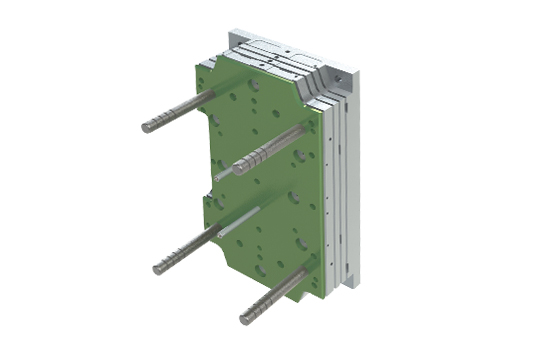

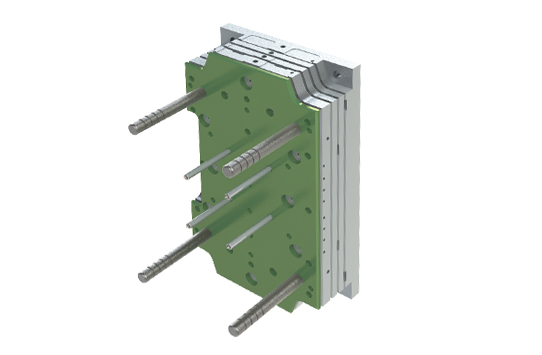

LSR Cold Runner System

Features and instructions

Specification

單位:mm

| Type |

Nozzle diameter |

Cavity diameter |

| CVRT-10 | Ø 12.7 | Ø 14 |

| CVRT-20 | Ø 20 | Ø 22 |

| CVRT-30 | Ø 38 | Ø 40 |

Liquid Injection Molding (LIM) process

Liquid injection molding uses a mechanical mixing process that focuses mainly on liquid silicone rubber (LSR) and similar elastomeric materials. Most of liquid silicone rubber products are made by injection molding. Mix material A and B of the dosage system and then each material will be pumped in a 1:1 ratio into a static mixer, which triggers the mixing reaction. The liquid mixture is then injected into a sealed mold and heat the mold for solidification.

process.jpg)

Features of Silicone

1. Excellent temperature stability:

It can be used stably without deterioration in the temperature -40 ℃ ~ 200 ℃.

2. Good weather resistance:

It can be placed for a long time outdoors, not aging hard, cracked, and peeling off.

3. Excellent shock absorption:

After the curing of silicone products, they are excellent toughness elastomeric. It has a good shock-absorbing effect.

4. Excellent electrical characteristics:

Silicone itself is a mineral, so it has excellent insulation, so it is very suitable for electronic products.

5. Excellent water repellency:

Organic silicone also has a waterproof, which is the use of electrical equipment in the wet conditions with high reliability protection.