Thermoplastic molding

Features and instructions

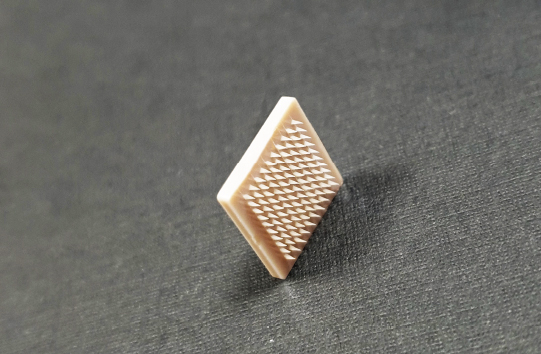

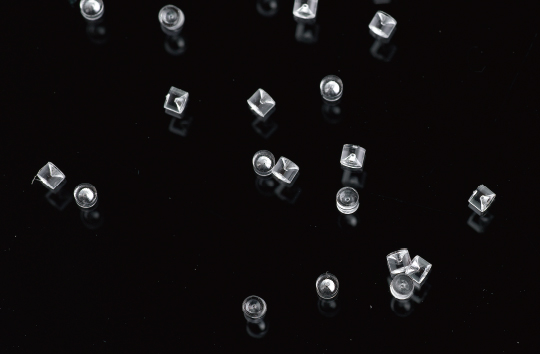

We provide fast and efficient solutions for micro-injection molding. We accept small batch orders starting from a minimum of 300 pieces. Our capabilities cover a wide range of product weights, from 0.0001g to 6g, and product sizes ranging from 1mm to 20mm. We can mold various thermoplastic materials, including elastomers, high-temperature plastics, and reinforced plastics. Examples of moldable materials include TPE, TPU, PP, PE, ABS, POM, PA, PC, COC, LCP, PEI, PPSU, and PEEK.

Mold design

OEM

Automation integration equipment

Features / strengths

1. Medical Expertise:We possess an in-depth understanding of the medical field's requirements, ensuring that the design and molding of micro medical plastic components adhere to the highest medical standards.

2. High-Precision Manufacturing:With advanced micro injection molding technology and precision equipment, we achieve high-precision manufacturing of micro plastic parts, guaranteeing consistency and reliability.

3. ISO 13485 Certification:Our ISO 13485 quality process certification ensures that our products meet medical-grade standards, and stringent quality control is maintained throughout the production process.

4. Cleanroom Production:Our production area is equipped with a Class 10,000 cleanroom, ensuring a sterile environment that upholds both product hygiene and reliability.

5. Comprehensive Services:We provide end-to-end services from conceptual design to batch production, ensuring that each step, from initial design to final delivery, meets the highest standards.

6. Mass production:We accommodate small batch orders, offering flexibility to meet customer demands and providing high-quality products within a short timeframe.

7. Material Selection:We can mold various thermoplastics, elastomers, high-temperature plastics, and fiber-reinforced plastics, offering a diverse range of material choices.

( View the Other Products here )