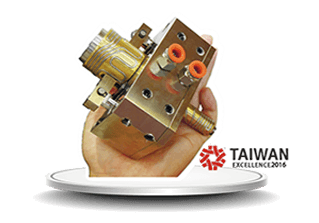

NOZZLE

Features and instructions

- Hot runner system nozzle is designed according to different product requirements. There are two types of open gate and valve gate hot nozzles.

Advantages of hot runner system

- Reduction in scrap and maunal operstion such as sprue trimming and scrap crushing.

- Cycle time reduction : hot runner could help runner freeze more quickly and simplify molding process such as runner removing.

- Make the most of machine capability : less reaction force from hot runner system, shorter cycle time, less clamping force.

- Engry save : Engry is spent on preparation stage to heat up maniflod and materail. But there will be less engry input when molding process begins.

- Simplify mold design and enable automated production.

- For big part, hot runner system could help solve pressure loss issue when using cold runner system.

- A less pressure loss could help injection more efficiently.

- Continuous packing effect could help reduce part shrinkage.

- By temperature control and valve gate control, hot runner system could make flow balance more easily.

- A sequence controled valve gate system could help produce a weld line free part.

OPEN GATE

- Simple and easy to use.

- According to the necessary, we can choose by using Sprue gating or Pin-point gating nozzle.

- The sprue nozzle is the most popular type. Not only it's suitable for almost all of the plastic material but also it provides easy color change.

- The pin-point gating nozzle:It provides good gate mark, reduction in raw materials consumption, and reduction of finishing work on molding.

- There are AESB, ANPR, ANPT, NL-ANPT and other specifications.

VALVE GATE

- No stringing, no drooling, no residue in the gate. Very good gate mark.

- Because it can provide bigger gate size, therefore it is very suitable for big size injection molding. Also lower injection pressure and less stress during molding.

- A sequence controlled valve gate system could help produce a no weld line part.

- We provide AVMT, SVDT, NL-SVDP, SVG types.

Related Products

( View the Other Products here )