Hot Runner Controller

Features and instructions

- High speed CPU.

- Panel with high brightness LED.

- With self - debugging function.

- PID controled.

- K, J type can be used.

Features

● Hot runner controller is a temperature controller used to control the temperature in the hot runner system.

● When used for production or for preheating, hot runner controllers ensure the most stable material temperature possible in each injection phase.

● 1 or 2 zone hot runner controller for hot runner system is attached with magnetic basis for fix in the machinery with safety.

● Not only easy to operate but also has a small size.

● With anomaly detection function to protect the system and the PID control to achieve high accuracy temperature control.

● Built in high speed CPU to keep the high stability and real time control.

1. Soft start mode for longer heating element usage.

2. Two temperature units °C and °F setting.

3. Microprocessor based self-tuning temperature controller with PID algorithm.

4. Advanced temperature compensation design.

5. 3 phase power lights ensure proper input voltage connection.

6. Sophisticated protection for power and current surge.

7. Basic and advanced parameter setting menu with keypad lockout protection.

8. Alarm temperature range setting.

9. High sampling rate 50ms for very precise temperature regulation during molding pro- cess.

10. Automatic self-diagnostics ability and error code warming.

11. Dual displays for output power percentage reading, current reading, set temperature and etc.

12. Changing increment and decrement value by pressing up or down button.

13. Two ways of power output control:one is Zero-cross control, another is Phase angle control.

14. Accepts two types of thermocouple J or K input.

15. 5 LED indicators for different operating status.

16. CE compliant.

Descriptions

1. Operating temperature:32 to 131°F (0 to 55°C)

2. Shipping temperature:-40 to 158°F (-40 to 70°C)

3. Humidity:10 to 95% non-condensing

4. Sensor type:J or K thermocouple

5. Sensor range:32 to 827°F (0 to 470°C)

6. Sampling rate:20ms

7. Temperature accuracy:±0.3% of span

8. Control output device type:Triac, 15A at 120/ 240 Vac; Optional 30A.

9. Operator Activation/ interface:4 momentary switches, 16A power switch.

10. Power requirements:85 to 250V 50/ 60 Hz nominal.

| N0. | Features | Amold | Others |

| 1 | Soft start function | ✓ | ✓ |

| 2 | Two temperature units °C and °F setting. | ✓ | ✓ |

| 3 | Auto and Menual function | ✓ | ✓ |

| 4 | Microprocessor based self-tuning temperature controller with PID algorithm | ✓ | ✓ |

| 5 | K, J type can be used | ✓ | ✓ |

| 6 | 6 kinds of Alarm output | ✓ | ✓ |

| 7 | Fuse failure indicator | ✓ | ✓ |

| 8 | Thermocouple failure indicator | ✓ | ✓ |

| 9 | Heater failure indicator | ✓ | ✗ |

| 10 | Data lock | ✓ | ✗ |

| 11 | Current output indicator | ✓ | ✗ |

| 12 | Fuzzy Tuning function | ✓ | ✗ |

| 13 | 220V~380V(50-60Hz) input power | ✓ | ✗ |

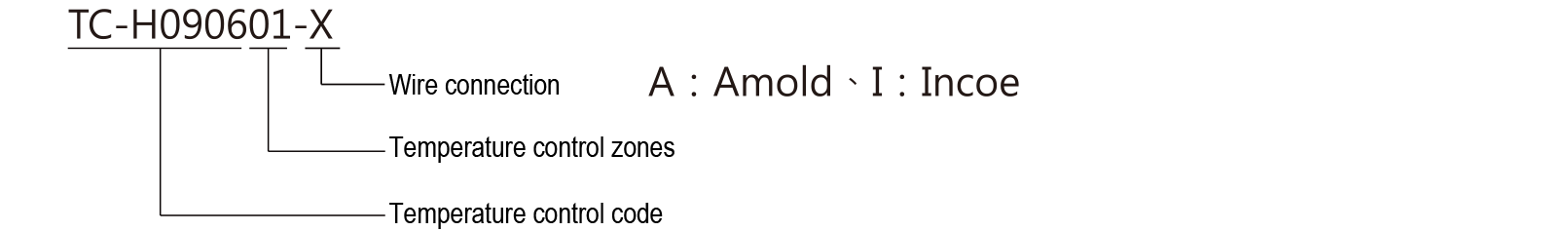

Specification

| Model | Input Voltage |

Appearance Dimension (L x W x H cm) |

Weight (kg) |

| TC-H090601-X | 220 V | 7 x 26 x 20.5 | 6 |

| TC-H090602-X | 220 V | 23 x 30 x 20.5 | 8 |

| TC-H090604-X | 220 V | 35 x 33 x 24.5 | 15 |

| TC-H090606-X | 220 V / 380 V | 45 x 33 x 24.5 | 20.8 |

| TC-H090608-X | 220 V / 380 V | 55 x 33 x 24.5 | 28.8 |

| TC-H090612-X | 220 V / 380 V | 75 x 33 x 24.5 | 32.8 |

Temperature Controller (Communication type-6 Zone)

- The series zone controllers offer many advanced features designed to increase productivity and ensure fast, accurate and repeatable mold temperature control.

- Compatible with D-M-E company’s G SERIES and SMART SERIES , ITC, MCS, YUDO and INCOE hot runner system temperature controller mainframes.

- Simultaneous display of both process/ set point temperature and process temperature / percent power output or heater current.

- Auto tuning independently adjusts zone control characteristics.

- Built-in diagnostics alert operator to fault conditions.

- Soft start circuitry design provides for safe heater warm-up through gradual phase-angle fired voltage control (soft start) or zero-crossing control (less interference).

| Model |

Appearance Dimension (L x W x H cm) |

Weight(kg) |

| TBP-1607-06 | 40 x 36 x 22 | 20 |

Related Products

( View the Other Products here )